By Rob Baker, Regional Service Superintendent | Northern CA & NV

In 2020, the American Innovation and Manufacturing (AIM) Act was passed by Congress to reduce the production and consumption of hydrofluorocarbons (HFCs) by 85% by 2036. HFCs are potent greenhouse gasses with high global warming potential (GWP). As part of this phase-out R-410A, a refrigerant commonly used in commercial HVAC systems, is being taken off the market.

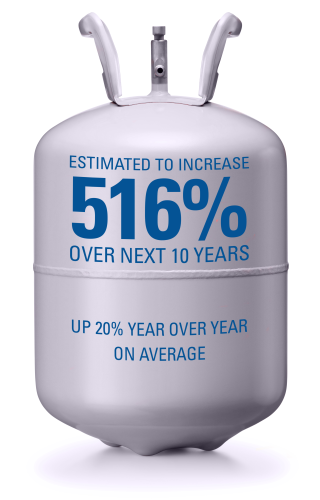

R-410A became the preferred refrigerant for commercial air conditioners following the ban of R-22 in 2010 as part of the Montreal Protocol, an international treaty with the goal to protect the ozone layer through the ban of substances that cause ozone depletion. Production and importation of R-22 has been banned since January 2020 with the only available sources being what was stockpiled or recovered from existing equipment. The resulting scarcity of product has driven prices of R-22 up roughly 20% year over year, or approximately 516% over the past 10 years. The expectation is that R-410A will follow a similar price escalation, and as such, the industry now begins what is becoming a cyclical search for the next “go-to” refrigerant.

What should you do?

What should you do?

At a minimum, here are the top three things you should know about the upcoming refrigerant ban:

- If your current HVAC system is well within its useful life with no performance issues, you don’t need to worry.

- If your facility has a large built-up DX System, you should talk with your ACCO project manager about alternative refrigerants that can be used if your system needs to be converted before the end of its useful life.

- If your HVAC system utilizes R-134A or R-410A and has experienced refrigerant leakage, you should be prepared for the increased costs of these refrigerants as time passes.

If alternative refrigerants are needed, ACCO’s highly knowledgeable and experienced OEM-certified technicians can assist in determining the best fit for your facility. R-410A operates at higher pressures than other refrigeration systems, requiring the use of specific parts that were specially designed for use with it. Due to the complexities of R-410A, manufacturers require certified technicians who install R-410A systems to be aware of the unique tools, equipment, safety standards and techniques that must be used.

Typically, we see more of the built-up DX systems in more remote regions with fewer high-rise buildings, including the Inland Empire, Sacramento, Reno, Las Vegas, Phoenix and Boise. Oftentimes, these are also the geographic regions with extreme temperatures that make a well-functioning commercial HVAC system critical.

Because R-410A operates at a higher pressure than other refrigerants, facility engineers need to carefully evaluate what is the best option for their overall system when making repairs. Unfortunately, this might include replacing well-functioning portions of a system to better match the overall refrigerant needs created by the portion that is being repaired. The cost of these repairs plus replacements can quickly escalate to the tune of tens of thousands of dollars and can continue climbing to hundreds of thousands of dollars.

Solutions ACCO can provide:

The replacement of R-410 with alternative refrigeration with lower global warming potential (GWP) has already begun. These alternatives include hydrofluoroolefins, hydrocarbons and carbon dioxide, but each has its own advantages and disadvantages. Facility engineers and property managers should be prepared for the phase-out to continue to impact additional refrigerants in the future. ACCO helps manage the increased costs associated with these phase-outs by maintaining deep relationships with our refrigerant suppliers, which allows us to pass our cost savings to our customers. However, the most impactful solution is to include your ACCO project manager in your capital budget planning allowing us to provide up-to-date advanced notice of changes that impact equipment selection and more.

Furthermore, your ACCO project manager can help you to better understand your system life expectancy and the pros and cons of system retrofits, such as reduced efficiency/efficacy and their associated costs over time. Property owners should also understand that these changes don’t result in plug-and-play solutions. New equipment could warrant structural engineering with changes and permitting to execute – there is no such thing as like for like.

Overall, the most effective way to minimize impact is to maintain a good working relationship with a trustworthy and capable partner that has engineering and field resources with deep experience in the nuances of system design and maintenance.

The complexity of your commercial HVAC system requires the utmost care and expertise to ensure lower operating costs throughout its long and effective lifespan. Reach out today to prepare yourself and your team with effective strategies that will help you navigate current and future refrigerant phase-outs.